So there has been lots of talk on which head is better. GE or GTE. Each has its advantage and disadvantages.

A few of the noticiable differences are

NA has higher intake ports and larger exhaust ports

TT has larger intake ports

Both heads flow about the same, some have stated that the NA heads actually flow better than TT heads(with at least factory cams)

I truly believe the NA head can actually flow BETTER than the TT head due to the port sitting up higher in the head, although I could be wrong, that is just my thoughts. But this can all be changed in the port/valve work.

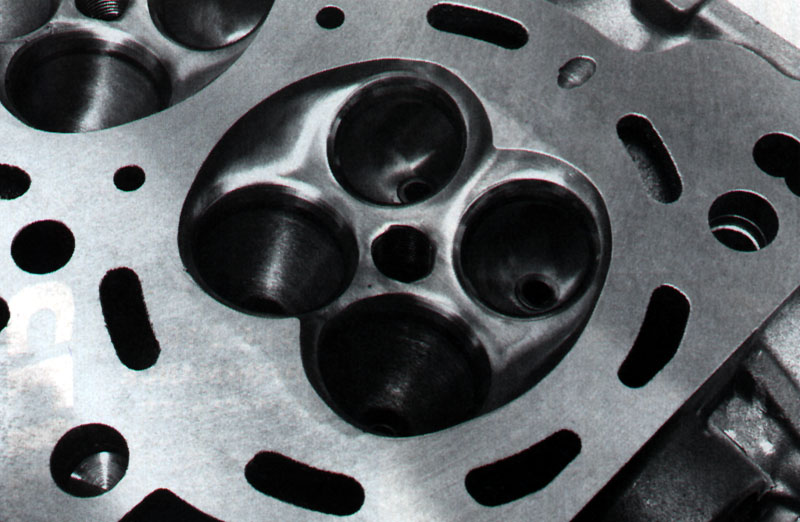

What I think it really comes down to is the SQUISH or QUENCH area. These are where the two heads really have a difference and can really change the combustion characteristics.

Please discuss:

A few of the noticiable differences are

NA has higher intake ports and larger exhaust ports

TT has larger intake ports

Both heads flow about the same, some have stated that the NA heads actually flow better than TT heads(with at least factory cams)

I truly believe the NA head can actually flow BETTER than the TT head due to the port sitting up higher in the head, although I could be wrong, that is just my thoughts. But this can all be changed in the port/valve work.

What I think it really comes down to is the SQUISH or QUENCH area. These are where the two heads really have a difference and can really change the combustion characteristics.

Please discuss: